current scan shunt

Simple methode for current density distribution measurement in fuel cell stacks.

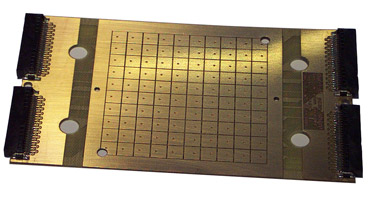

Sensor plate of type current scan shunt for a 50cm² cell

The devices of type current scan shunt allow:

+ detailed analysis of flow fields

+ detailed analysis of materials

+ optimization of fuel cells

+ fault diagnostics in fuel cells

+ long-term tests

+ resolution depends on design

+ current range depends on design

+ standard devices are available

+ special designs on request

+ mass production possible

With the current scan shunt, the current density distribution in fuel cells can be measured. Because of the simple internal structure it is suitable for mass production. It is easy to use and the evaluation electronics can be connect via USB to any computer.

In a fuel cell the local conditions differ, which leads to an inhomogeneous mass conversion resulting in an inhomogeneous current production. One of the keys to a better understanding of PEM fuel cells, DMFC and other electrochemical cells is the measurement of the current density distribution. It is important for a save and reliable operation as well as a high lifetime.

Application

The device of type current scan shunt shown above has a resolution of 10 x 10 measurement cells and an active area of 50cm². Because of the simple internal structure it is suitable for mass production. So the current scan shunt can also be applied in series production of fuel cells. It can be used for example for control applications. The picture below shows the sensor plate.

current scan shunt sensor plate

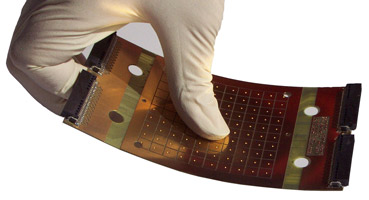

The sensor plate shown above has a thickness of 0.7mm.

Because the sensor plates are very thin they can be laminated together with a thicker part where arbitrary channals can be milled into the surface. So if it is wished by the customer the senor plate can be used as a flow field and the gas diffusion layer can be placed directly on the gold plated sensor plate. The sensor plate can be placed at an arbitrary position in the stack.

Because of the simple internal structure the sensor plates are suitable for mass production.

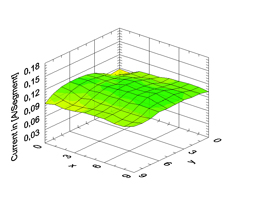

The next picture shows a typical current distribution.

Measurement data

Measurement Principle

The devices of current scan shunt series use a low ohmic shunt resistor for current measurement. We produce two different designs. The first one is made out of material with a very low temperature coefficient. In this case the measurement is temperature independend and no further calibration is necessary. This is an efficient and easy way for measurement. The following picture showes some of the internal resistors during production.

Internal resistors of current scan shunt

The second design is made from a special copper layer. Because of the high temperature coefficient of copper a temperature compensation is necessary during the measurement.

The current scan shunt is produced in licence of the DLR (German Aerospace Center).

For both designs the signals from the shunt resistors are connected to a multiplexer which automatically switches the signals to an amplifier and evaluation electronic with Analog-to-Digital converter. This is shown in the following picture.

Principle of current scan shunt

The resolution is limited, because of the complexity. The complexity grows quadratically with the number of rows and colums of measurement cells. For each measurement cell two wires are necessary, therefore for an array with n x n measurement cells 2n² wires are necessary.

So the current scan shunt is the best choice if there is enough space for the wires, especially for small fuel cells or when a low resolution is sufficient.

For large fuel cells we recommend the current scan lin device of our successful current scan product line, which works in a different way and has a linear complexity.

Available standard devices

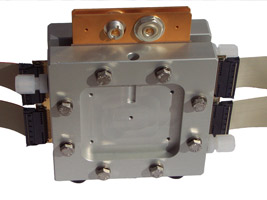

Standard devices are available with 25cm² and 50cm². The following picture showes a sensor plate equiped with flat ribon cables to the electronic, inserted into a 50cm² single cell fuel cell.

current scan shunt in 50cm² single cell fuel cell

The data acquisition system is equiped with a USB interface.

Custom made devices

We realize nearly any custom required design. The only restricion for the measurement cells is the available space for the internal wires. The maximal size is nearly not restricted and depends only from the technical producibility.

Specifications

| general data | |

| current measurement range | a wide range is possible |

| measurement time for current | depends on the amount of measurement cells and evaluation electronic |

| position of measurement | at an arbitrary position in a stack up to 60V (higher optional) or single cells |

| sensor plate | |

| segments | gold plated |

| size of measurement cell | depends on the design |

| thickness | 0.7mm |

| maximum operating temperature of sensor plate | 100°C |

| electronic | |

| analog switches | 40 per board, can be cascaded |

| interface | USB-Interface |

| power supply | over USB |

| operating environment | 0-40°C, humidity: no condensation |

| software | user interface and device drivers for Windows 2000 and Windows XP |